Additive Injection in Well Field using Wing Nut

Additive Injection in Well Field using Wing Nut Industry

Oil and Gas Field Services – Turbine flowmeters, meter liquid and gas additives

SIC Code

1389

Application

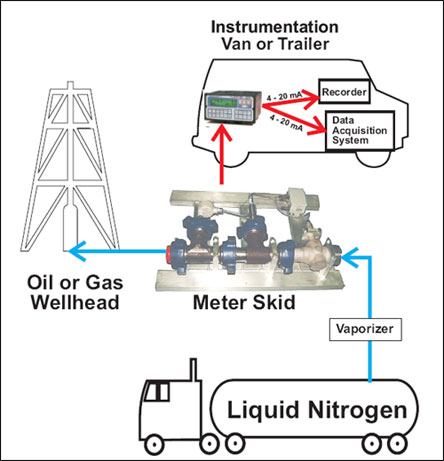

There are several companies worldwide that provide oil and gas well field services. One of the services offered provides for enhanced output from the well. The service company injects various additives into the wellhead. Turbine flowmeters are commonly used to meter the liquid and gas additives. A specific application identified by Dowell Schlumberger of Sugarland, Texas, is for monitoring high-pressure gaseous nitrogen at 0 – 10,000 PSI pressures. During the injection process, Dowell Schlumberger monitors several process variables to improve the well’s output ultimately.

System Requirements

Accurate overpressure range 0 – 10,000 PSI.

Rugged to withstand harsh field conditions of oil fields.

Lightweight for transportation between sites.

Totalize output of nitrogen gas in mass units.

Provide compensated analog output for the data acquisition system.

Solution

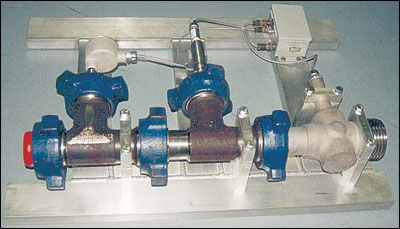

Hoffer Flow Controls and Dowell Schlumberger have designed a metering skid that incorporates a turbine flowmeter and mass flow computer. The skid consists of the following:

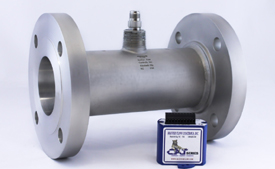

–Wingnut turbine flowmeter designed for pressures up to 15,000 PSI.

-Wingnut housings to accommodate the installation of high-pressure temperature and pressure transducers.

-Mass flow computer.

-Aluminum frame supports the meter run and is used to carry the meter run.

-A manifold collector box that accepts independent signal inputs from flow meters, temperature transmitters, pressure transducers. The collector box provides one cable assembly that carries all process signals to the remote mass flow computer.

Hoffer Advantage

Wingnut turbine flowmeter is rugged and designed for oil field conditions. Flowmeter provides a wide operating flow range that is usable over the wide operating pressure range. Mass flow computer provides mass flow calculations and corrects for temperature, pressure, and compressibility. Flow computer incorporates “high alarm” to monitor flow rates that could occur over the turbine flowmeter range. Flow computer improves flowmeter linearity via linearization

Summary

The flow system allows the customer to monitor mass flow during the good treatment accurately. Based on the information obtained from the system, they can adjust the treatment of the wellhead to provide for optimum product output.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

Also, see

Turbine flow meters

Cryogenic Flowmeters

Turbine flowmeters, meter liquid and gas additives

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News