Shipboard Reverse Osmosis Flowmeters | Reverse Osmosis Systems

U.S. Navy Shipboard R/O Systems Use Hoffer Flowmeters

Hoffer Flow Controls is a supplier of flow products to various agencies within the U.S. government, including the Navy. We have supplied flowmeters and flow switches for many shipboard applications.

Along with the U.S. Navy, our customers include prime contractors such as Ingalls Shipbuilding, Bath Iron Works, and Newport News Shipbuilding. Systems supplied to these customers include fuel flow measurement systems for the propulsion plant, missile cooling systems, trim and drain systems, and flow switches for use in the fire control system.

Recently, we have worked with a major supplier of reverse osmosis (“R/O”) systems for use on the U.S.Navy DDG-51 Class Destroyer. This class of ship, which carries weaponry for battle, is 505 feet overall in length and carries a crew of 341.

R/O systems will handle “all” shipboard water requirements

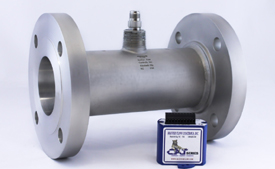

Hoffer is supplying the turbine flowmeters used on both the supply and discharge sides of the R/O systems. The R/O systems will handle “all” shipboard water requirements. The supply-side flowmeters are suitable for use on seawater. Thus, they are constructed of naval bronze and monel.

These materials provide long life against seawater’s corrosive nature. The flowmeters on the discharge side are constructed of 316 stainless steel and will meter the potable water. All flowmeters will supply simultaneous pulse and analog outputs fed to the ship’s main control room.

Historically, the Navy has employed gauge-type flowmeters whereby the “roving watch” was responsible for taking and recording readings. The information obtained from the supply and discharge flowmeters on the R/O plant enables the crew to determine the efficiency of the R/O system.

With precision output flow information, the Hoffer turbine flowmeters will enable the Navy to minimize workforce requirements onboard the vessel. This is one of the design goals of this class of ships.

Mil-S-901D shock requirements

The Hoffer turbine flow system incorporates a robust design tested to meet Mil-S-901D shock requirements, Mil-Std-167-1 mechanical vibration requirements, and Mil-Std-462D EMI requirements. The Hoffer flowmeters have been first article tested and certified by independent laboratories to meet these Military standards. These flow systems are available in various sizes supporting flow ranges starting at .25 GPM through 12,000 GPM.

The Hoffer “Navy design” turbine flowmeter is well suited for this application because of its robustness, versatility concerning construction materials, and reliability. “Bath Iron Works had recommended that the R/O system manufacturer contact Hoffer for the turbine flowmeters needed for their system,” according to Linda Markham, account manager for the project.

“This speaks volumes about the long-term reliability of the Hoffer systems,” she indicates, “because Bath Iron Works has been using the Hoffer turbine flowmeter for a variety of shipboard applications for years.” Now, in addition to supplying flow systems for the propulsion plant and other critical shipboard flow processes, Hoffer has also provided a solution for the R/O water plant.

Hoffer provides flow systems for simple and customized applications. Call us today with your flow requirements.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality liquid turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Controls on Linked In

Shipboard Reverse Osmosis Flowmeters from Hoffer Flow Controls

Hoffer Turbine Flowmeters are available in a broad range of standard and special materials. The wide range of construction options allows for selecting the optimum combination of useful range, corrosion resistance, and operating life for a particular application. A low mass rotor design allows for a rapid dynamic response which permits the turbine flowmeter to be used in pulsating flow applications.

Also, see

Hoffer Flow systems used on LCS 19, USS St. Louis

What happens if the flow goes in the reverse direction in the meter?

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News