Turbine Flowmeters Diesel Fuel Application in Diamond Mines

Fuel turbine flow meters, Flowmeter measurement applications

You’ll Even Find Us in the Harshest Environment in the World.

Mining worldwide for minerals from coal to diamonds is an enormous industry, with annual sales measured in trillions of dollars. Most mining activity occurs in remote locations, miles from the nearest conventional sources of power.

Mining operations also entail the bulk movement of earth and minerals on a massive scale. Electric power is generated on-site via diesel engine-driven and/or steam-driven generators in most of these operations.

Accurate Accounting of Diesel fuel

Diesel fuel can only be brought into the mining sites in bulk at specific times of the year. Mines in the polar or near-polar regions can only bring in fuel when the ground is frozen to the point that the soil will support the weight of the transport trucks.

However, the transportation cycle must be completed before the full onslaught of winter conditions that make such transport overland extremely hazardous, if not impossible. Diesel fuel is also hazardous in the accidental release into the environment and is often regulated by local jurisdictions.

For all these reasons, the accurate accounting of diesel fuel received, dispensed, and consumed at a remote mining site is of extreme importance to the proper operation of the mine. Hoffer Flow Controls has the breadth of solutions to help make this task easier with our state-of-the-art Fuel flow meter systems, Flowmeter measurement applications.

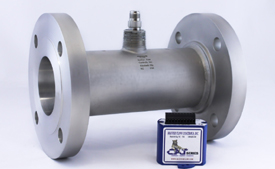

Under some of the harshest conditions on the planet Conflow Technologies, our Canadian Representative can provide Hoffer turbine flowmeters as a solution to one of the world’s largest gold and diamond mining companies.

Located in Canada’s Northwest Territories, the site includes its own diesel fuel-fired power and steam generation plant and employed over 200 pieces of diesel-powered mobile mining equipment.

Measuring Diesel Fuel

While working on the initial application, Conflow learned of additional requirements for measuring diesel fuel. The applications included fuel being received on-site and transferred from bulk storage facilities to individual points of use in the power generation plant and a second application at dispensing points for fueling the mobile equipment. These applications were all ideal matches for Hoffer turbine flowmeters.

Conflow has installed 25 Hoffer turbine meters at the site for the following applications.

Hoffer turbine flowmeters are installed on all bulk fuel receiving lines. The receiving lines are equipped with air eliminators supplied by Conflow Technologies. These meters are used to verify the actual fuel received from the tanker trucks.

Two main distribution lines from a tank farm feed fuel to various secondary tanks located at various stations in the mine. Hoffer turbines are installed on these two distribution lines. This allows the mine to track its main fuel inventory. (Fuel received versus fuel transferred.)

Each of the secondary distribution lines is equipped with Hoffer turbines. These include heavy equipment refueling stations, along with boiler fuel consumption applications in the powerhouse. These flowmeters allow the mine to track the fuel each department uses. The flowmeters were calibrated for the average viscosity of P40 diesel fuel oil @15°C.

Insertion Turbine Flowmeters

The Arctic has a very fragile ecosystem. The mining company is susceptible to this. Therefore it has installed insertion turbine meters on various fuel lines to indicate fuel leakage or valve malfunction. These flowmeters are interlocked with their existing automation system.

Hoffer insertion turbine flowmeters are also used to de-water lakes, where the meters measure the volume of water pumped from the lake. This is also a requirement set by the environmental authorities.

A requirement at the site is for all fuel flow systems to be corrected to 15°C to match the correction on incoming fuel deliveries. This necessitated electronic flow computers that can perform these corrections, which Hoffer was able to supply.

Our flow computers with additional equipment from Conflow provide data acquisition and printing capabilities. The Hoffer flow computers provided CSA and Canadian Weights and Measures approvals.

Thanks to Conflow Technologies for a great job supplying the customer with solutions to their multiple flow measurement applications.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News