Turbine Flowmeters Spare Internals and Parts

Turbine Flowmeters Spare Internals and Parts

Replacement Parts and Calibrated Internals

Hoffer turbine flowmeters are easily repaired in the field with a minimum number of tools. A spare complete set of calibrated internals can provide nearly continuous operation of a flowmeter that has been damaged or needs to be recalibrated and are available in all sizes.

Calibrated kits are supplied with a NIST traceable calibration datasheet. For detailed technical information, refer to the “Hoffer Engineering Guide.” When ordering a replacement or spare parts, please provide the Hoffer model number or the serial number of the original unit.

Principle of Operation:

Hoffer inline turbine flowmeters are velocity measuring devices, which is to say they measure the average velocity of a fluid flowing through the meter’s body. Mounted within the body of a Hoffer liquid turbine flowmeter is a vaned rotor.

The rotor is centered on a shaft and allowed to rotate utilizing bearings. The shaft is supported in the housing by tube bundles that measure flow conditioning for the fluid stream.

The rotor is made from a ferromagnetic material or contains a magnet within the hub of the rotor. Liquid flowing through the meter body engages the rotor forcing it to rotate. The rotational velocity of the rotor is proportional to the average linear velocity of the liquid flow stream.

This rotational velocity is transformed into an electrical frequency signal utilizing a non-intrusive sensor or coil threaded partially into the meter’s body aligned with the rotational circumference of the rotor. Being close to the ferromagnetic or magnetic rotor creates an electromagnetic coupling with the coil.

The output frequency of the coil is then directly proportional to the rotational velocity of the rotor. This frequency can then be converted to a flow rate indication or scaled signal by dividing the frequency by the meter’s scaling or K-factor (e.g., pulses per gallon or pulses/liter).

The K-factor is established by factory calibration of the flowmeter at the time of manufacture.

About Hoffer Flow Controls

Hoffer Flow Controls has been designing and manufacturing quality liquid turbine flowmeters and related process instrumentation for more than fifty years. Our initial experience was in the field of cryogenic flow measurement. Today our reputation in this field is synonymous with quality. Today Hoffer Flow Controls manufactures high-precision turbine flowmeters to measure clean liquids and gases throughout the processing industries. Please be sure to follow Hoffer Flow Control on Linked In

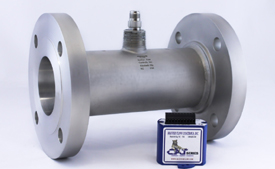

Gas Series Turbine Flowmeters from Hoffer Flow Controls

Hoffer Turbine Flowmeters are available in a broad range of standard and special materials. The wide range of construction options allows for selecting the optimum combination of useful range, corrosion resistance, and operating life for a particular application. A low mass rotor design allows for a rapid dynamic response which permits the turbine flowmeter to be used in pulsating flow applications.

Also, see

Turbine flow meters

Cryogenic turbine flow meters

FLOWMETERS BY INDUSTRY []

LIQUID TURBINE FLOWMETER APPLICATIONSAND GAS TURBINE FLOWMETER APPLICATIONS[]

-

Liquid Applications

We provide best solutions that will meet the extreme conditions

associated with your subsea and oil and gas applications.LEARN MORE []We provide best solutions that will meet the extreme conditions associated with your subsea and oil and gas applications.

-

Gas Applications

We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

LEARN MORE []We offer complete flow measurement packages for the offshore drilling, production and well-servicing environments.

Company News

Company News